Preparation of mesophase pitch from Vietnam coal as precursor for manufacturing high modulus carbon fiber

TRAN SI TRONG KHANH1,2, NGUYEN PHUONG HOAI NAM1, NGUYEN NANG DINH1

1 Faculty of Engineering Physics and Nanotechnology, University of Engineering and Technology, Vietnam National University, 144 Xuan Thuy, Cau Giay, Hanoi

2 Research Institute for Application and Transfer of High Technology, Vietnam Union of Science and Technology Associations, Nguyen Du, Hai Ba Trung, Hanoi

Email: transikhanh.2012@gmail.com

Ngày nhận bài: 6/6/2020, Ngày duyệt đăng: 25/9/2021

ABSTRACT

To obtain a raw material for synthesis of carbon fiber with high elastic modulus (tensile), a material of mesophase pitch was fabricated from Vietnam coal by heat treatment under different technological conditions. Analysis of dependence of the chemical composition, viscosity and volume change of the pitch on heating temperature, holding time and heating rate shows that the phase transformation kinetics in this coal pitch can be realized by an optimized technology regime, in which temperature and heating rate play an important role. The pitch material received has a high carbon content of over 80 wt. % and a low sulfur content of less than 5 wt.%, meeting the requirements of being a precursor for carbon fiber with high elastic modulus.

Keywords: mesophase pitch, coal pitch, carbon fiber, high modulus

TÓM TẮT

Nhằm tạo nguyên liệu để tổng hợp sợi cacbon có môđun đàn hồi (kéo) cao, một pha trung gian là nhựa đường đã được chế tạo từ than đá nội địa bằng phương pháp gia nhiệt, theo các điều kiện công nghệ khác nhau. Phân tích sự phụ thuộc của thành phần hoá học, độ nhớt, sự thay đổi khối lượng nhựa đường vào nhiệt độ nung, thời gian giữ nhiệt và tốc độ nung, cho thấy động học quá trình chuyển pha trong nhựa đường từ than đá có thể thực hiện bằng một công nghệ tối ưu, trong đó nhiệt độ và tốc độ nung đóng vai trò quan trọng. Vật liệu nhựa đường nhận được có hàm lượng cacbon cao trên 80 % k.l. và hàm lượng lưu huỳnh thấp dưới 5,0 %k.l, đáp ứng yêu cầu làm nguyên liệu chế tạo sợi cacbon có môđun đàn hồi cao.

Từ khóa: pha trung gian nhựa đường, sợi cacbon, nhựa than đá, môđun đàn hồi cao

1. INTRODUCTION

Properties of mesophase pitch-derived coke, mesocarbon microbeads, mesophase pitch-based carbon foam, high-modulus mesophase pitchbased carbon fibers, and high-thermal-conductivity carbon-based composites, etc. can be seen in a review of Yuan and Cui [1].

The formation process, structure and properties of carbon fibers (CF) is well reported by Rigg in a review article [2] and by Newcomb in [3]. Highelastic modulus carbon fibers are widely used in everyday objects and aerospace (high-modulus CF). They are usually made of coal or petroleum pitches. In the heat treatment process of the pitch fiber to obtain a carbon fiber with graphite structure, initially a small spherical structure with optical isotropic properties appears in the pitch, when viewed through cross polarizers. As the temperature or holding time increases, the spheres grow and then large spheres merge into larger structures and eventually, the isotropy is lost and the final structure becomes completely anisotropic.

Optical anisotropic material is called the mesophase. The nature of the mesophase and the mechanism of its formation are presented in [4-5].

Pitch fibers which are made by centrifuging, pulling or pressing from the coal or petroleum pitches due to formation of a mesophase, are called the mesophase pitch (MP) fibers. The carbon fibers fabricated from these fibers are highmodulus carbon fibers. Before production of pitch fibers, the pitch is treated from insoluble impurities in a number of solvents such as benzene, toluene, pyridine, quinoline and volatile substances available in the pitch. The pitch is then heated to initiate a mesophase. The product of this stage is the mesophase pitch. The process technology for preparation of the mesophase pitch has been reported in [4-12]). An improved process for preparing liquid-crystal containing pitches comprises extracting carbonaceous isotropic pitches with an organic solvent system was reported by Diefendorf et al. [13].

Yuan et al. [14] reported that by using six representative feedstocks as carbonaceous precursors, various mesophase pitches and their derived cokes by a heat-soaking method at a temperature range of 400−450 °C and a pyrolysis treatment at 900 °C were well obtained.

In this research, the results of manufacturing of mesophase pitches from domestic coal are presented as follows:

– Determining composition of the pitch to consider the possibility to fabricate high quality carbon fibers at a reasonable It should then choose the input material between a pitch of coal, petroleum or other material sources. Criteria for the production of high modulus carbon fibers are usually directed towards the use of pitches with a high carbon content (above 80 %) and low sulfur content (below 1-5 wt. %).

– Handling insoluble solid impurities in some solvents such as benzene, toluene, pyridine and These impurities have a great influence on structure of the pitch fiber and determine quality of the carbon fiber. After dissolving in solvent, the pitch will be filtered to remove insoluble impurities.

– Treating volatiles, grease and sulfur in the It is necessary to determine the amount of the impurity in the pitch after treatment in dependence on a number of technological parameters. The purpose of this is to keep the pitch clean which won’t contain any insoluble substances that will impede spinning or reduce mechanical proper-ties of the high modulus carbon fiber. In the process of centrifuging, spinning and pressing there will be no polymerization; otherwise it will change viscosity, create gas and leave bubbles in the pitch fiber.

– Evaluating the pitch viscosity as a function of temperature to select an appropriate viscosity in the manufacturing technology of mesophase pitch The viscosity of pitch depends on carbon content and is a function of heating temperature. The final quality of the high modulus carbon fiber depends on the viscosity during centrifuging, pulling or pressing the pitch to form a mesophase pitch fiber.

– Establishing the appropriate heating rate, temperature and holding time at the moment of appearance and development of a mesophase in the This is the stage of preparing the mesophase pitch before creating the mesophase pitch fiber. A heating process will be established for the pitch made from domestic coal or petroleum in the fabrication technology of carbon fibers.

2. EXPERIMENTAL

2.1. Materials

The domestic coal pitch is taken from the coking factory, which belongs to Thai-Nguyen Ironsteel Joint Stock Company (Vietnam). The coal pitch was heated in a HTC 08/16 high-temperature furnace (Figure 1a). Figure 1b shows the morphology of the initial coal pitch put on four cups. The baking cups of pitch are arranged in the furnace upto 1,280 °C. The cups were thermally treated at different heating rate (X), temperature (Y), and holding time (Z).

The pitch samples after heat treatment will be analyzed according to different sample symbols as PEKX-Y-Z.

2.2. Equipments and analytical techniques

The experimental equipments used include:

- High temperature furnace HTC 08/16

- Analytical balance XT 220A

- Calorimeter Parr 6200

- Memmert oven

A selected subject for study is the domestic coal pitch. The coal pitch has several advantages over petroleum one. It has a higher content of aromatic molecules, higher density, lower sulfur content, and higher viscosity. The coal pitch is produced from domestic mines, ensuring long-term stability, not dependent on foreign materials and of high quality compared to petroleum-based pitch. This input material is used to fabricate high-elastic modulus carbon fiber.

The composition of coal pitch samples is analyzed. The viscosity of pitch is temperature-dependent and is measured by the DV-II +Pro viscometer with the following parameters:

- Speed of rotation: 3 rpm

- Spindle type: number 4 (small type)

- Number of repetitions: 3 times

- Starting temperature: 100 °C

- Finishing temperature: 135 °C

- Viscosity unit: cP (1 cP is equal to mPa·s in the SI).

The preparation of samples, the method to choose pitch samples using specialized tools and the study of the effect of technological parameters on the structure and properties of pitches were conducted at the Research Institute for Application and Transfer of High Technology (IHT). The pitch is heated in SUS 304 steel cup in a furnace with an automatic temperature control program.

X-ray diffraction (XRD) analysis was carriedout on a Brucker “Advance-8D” X-ray diffractometer with KaCu wavelength l = 0.15406 nm.

3. RESULTS AND DISCUSSION

3.1. Chemical composition of the coal pitch

As above mentioned, in the manufacturing technology of high modulus carbon fiber, domestic raw materials are used. The coal pitch as a pitching material to make carbon fiber because of it’s high carbon content. The composition of pitch samples was shown in Table 1.

The carbon content of the Thai-Nguyen coal pitch is rather large (≈ 85.50 wt. %) compared to other domestic or Japanese samples, but the sulfur content of 1.24 % is larger, compared to 0.5 % found in petroleum pitch in report [15].

Table 1. Composition of Thai-Nguyen coal pitch

| No. | Indicator | Unit | Test method | Average content (wt. %) |

| 1 | volatiles | % | TCVN 174: 2011 | 13.14 |

| 2 | humidity | % | TCVN 172: 2011 | 0.12 |

| 3 | C | % | ASTM D3172 | 85.50 |

| 4 | S | % | TCVN 175: 1995 | 1.24 |

The analysis results show that the coal pitch meets the requirements used to fabricate high modulus carbon fiber and high density graphite according to previous Soviet standards (GOST No. 1038-75 [16]).

3.2. The viscosity of coal pitch

In our experiments we interested in the dynamic viscosity. The viscosity of a material, including coal pitch is a measure of its resistance to deformation at a given rate. Viscosity can be conceptualized as quantifying the internal frictional force that arises between adjacent layers of fluid that are in relative motion. The most commonly used unit for dynamic viscosity is the CGS unit centipoise (cP).

In the praparation of CF coal pitch by centrifucal technique, the temperature dependence of the viscosity of the pitch plays an important role. Thus it is necessary to characterize the viscosity of the pitch in order to find-out optimal conditions for further synthesis of CF.

The results of viscosity measurement of the coal pitch sample are shown in Table 2.

Table 2. The viscosity h (in cP) of the coal pitch at different temperatures

| No | Temperature (oC) | Test 1 | Test 2 | Test 3 | Average value |

| 1 | 100 | 456 | 503 | 486 | 481 |

| 2 | 105 | 512 | 525 | 506 | 514 |

| 3 | 110 | 544 | 567 | 630 | 580 |

| 4 | 115 | 600 | 694 | 669 | 654 |

| 5 | 120 | 782 | 733 | 695 | 736 |

| 6 | 125 | 824 | 768 | 785 | 792 |

| 7 | 130 | 977 | 813 | 846 | 878 |

| 8 | 135 | 1056 | 896 | 940 | 964 |

The viscosity dependence of the coal pitch on the heating temperature is shown in Figure 2. The results show that there is a linear relationship and it coincides with the results published in [17].

Ciesinska showed that the coal-tar pitch with phenol-formaldehyde resin has an increased thermal and mechanical resistance. Furthermore, phenol-formaldehyde resin has an effect on increase in the coal-tar pitch viscosity. It probably results from the increased content of components of higher average molecular mass in the pitch and lower solubility in organic solvents [18].

3.3. Change in pitch mass with heating temperature and holding time at constant heating rate of 10 °C/h

The purpose of this study is to find the effect of temperature and time of heat processing to eliminate volatile substances in the coal pitch before being pressed, pulled or sprayed into pitch fibers.

Before using pitch as an input material for fiber fabrication, the pitch is heat treated to remove moisture, volatile matter, and sulfur that is present in it. During heating process, the amount of pitch remaining after treatment depends on the heatìng rate, the temperature and the holding time.

Table 3 shows the pitch residue at different temperatures and holding times. In [19], the temperature range for preparation of the mesophase pitch is from 239 to 400 °C. In this study, the temperature range chosen for investigation was 275, 300 and 325 °C with holding times of 0, 45, 90 and 135 minutes. The results of measuring the pitch residue over time and temperature are shown in table 3 and figure 3.

Table 3. Pitch residue of the coal pitch at different temperatures and holding times with heating rate of 10 oC/h (wt. %)

| PEK10-275-0 = 95 | PEK 10-275-45 = 93 | PEK 10-275-90 = 92 | PEK 10-275-135 = 92 |

| PEK 10-300-0 = 94 | PEK 10-300-45 = 87 | PEK 10-300-90 = 85 | PEK 10-300-135 = 85 |

| PEK 10-325-0 = 86 | PEK 10-325-45 = 73 | PEK 10-325-90 = 68 | PEK 10-325-135 = 68 |

The mass of sample PEK0-0-0 before heating is considered as 100 %, there will be three curves as shown in figure 3. The change of sample mass at different heating temperatures and holding times with heating rate of 10 °C/h is quite obvious.

With the same heating rate of 10 °C/h the change in mass at different heating temperatures in figure 3 allows comparison of this change with the holding time. As time increases the pitch residue decreases gradually and the higher the temperature, the greater the decrease. It’s due to greater amount of substances evaporated from the pitch with higher temperature and longer time. At observed temperature range, after a period of ≥ 90 minutes, the mass of the samples was kept unchanged. This proves that at given temperature and time, the volatile matter in the pitch was completely removed.

Comparison of change in weight of the pitch sample after heating in correspondence with amount of evaporated volatile from the pitch shows that at a heating rate of 10 °C/h the chosen temperature of 325 °C is suitable for thorough treatment of volatile in the pitch.

3.4. Mesophase formation with different holding times at 10 °C/h and 325 °C

Briggs in [20] demostrated that at temperatures up to 200 °C, the viscosity of pitch, follows a predictable variation with temperature. Above 200 °C, variations occur depending on the source of the pitch, although a minimum viscosity is always achieved between 320 and 400 °C, followed by a rise. On heat treating at a constant temperature of 400 °C the viscosity rises. Although some preliminary work on two low-temperature pitches indicates a different regime, the work on coke-oven pitches shows a clear relation between viscosity rise and the formation of tolueneand quinoline-insolubles by what appears to be consecutive reactions from tar oils, during which the rheological behaviour becomes increasingly pseudoplastic.

As stated in section 3.3, at a temperature of 325 °C with a heating rate of 10 °C/h and a holding time of 90 minutes or more, the residual weight of pitch does not change, and at this temperature an mesophase is likely to form and develop. To clarify this, the structural changes of pitch were examined visually when the pitch sample was heated at 325 °C with different holding times (0, 45, 90 and 135 minutes). The surface morphology of the pitch sample over the different holding times is shown in figure 4.

It’s observed the mesophase began to appear on the pitch surface at a temperature of 325 °C with a holding time of 0 minutes (figure 4b). As is well known, with a very slow rate of heating (10 °C/h), the time for heating up from room temperature (25 °C) to 325 °C is 30 hours. During this time, the heat supplied to the system is mainly used for evaporation of volatile substances in the pitch. Only when the holding time of 90 minutes is reached, does the pitch phase appear on the entire pitch surface. The sample surface is, of course, provided with the heat by radiation, convection and heat conduction. And the material located deep inside the sample is only heated by heat conduction. Therefore, the internal temperature will be lower than that on the pitch sample surface. Although the pitch phase appeared on the surface of the pitch sample, it is unlikely to find this phase inside. To confirm the temperature and holding time favourable for a mesophase in the entire pitch mass, it is necessary to analyze the structure of the pitch by diffraction analysis. To recognize the appearance of pitch mesophase, the change in structure with temperature was investigated. Analysis results will be mentioned in section 3.5.

3.5. The pitch crystalline structure changes according to the heating temperature at 10 °C/h

The purpose of the analysis is to establish the temperature range at which the pitch mesophase occurs. The coal pitch samples were heated. To evaluate the structural change of pitch with heating temperature and to compare with the structure of unheated pitch samples, the crystalline structure of a room-temperatue (RT) sample and the samples heated at 150, 250, 350 and 450 °C was analyzed by using X-ray diffaction (XRD).

XRD patterns of pitch samples were plotted in Figure 5. It can identify structural changes of pitches in heating process at heating rate of 10 °C and final temperatures of (150 ÷ 450) °C.

Figure 5 shows that the XRD peaks corresponding to 2θ ≈ 25 o of the unheated pitch sample (PEK0-0-0) and heated samples (heated at 150 °C and 250 °C) are nearly identical. This proves that no new phase appears in the pitch. But the width of the diffraction peaks has narrowed, implying that crystallities formed from macromolecules in the pitch have grown up with the increase of the heating temperature. In this temperature range, only CH3 and H2 separation occurs. But at 350 °C, the XRD peak is gradually shifted to the right, toward the larger diffraction angle 2θ, moreover the peak become narrower. Thus, the pitch structure has begun to change and a new phase appeared. This is consistent with the conclusion stated in section 3.4. This means that in the temperature range above 325 °C, for coal pitch, a mesophase will be formed. Determination of the temperature and holding time is very important in the manufacturing technology of carbon fiber with high modulus.

3.6. Kinetics of pitch mesophase transformation in coal pitch

As mention in sections 3.4 and 3.5, the minimum temperature and time of mesophase appearance in the coal pitch have been determined. Another requirement is that how long the holding time is considered sufficient. Thus, it is necessary to study the kinetics of mesophase transformation. Therefore the mesophase percent will be determined with various holding time, when heating is kept at a certain temperature with the selected heating rate.

The dependence of the formed mesophase content on the holding time is shown in Figure 6. With the heating rate 10 °C/h at temperature 325 °C, the coal pitch is completely transferred to mesophase in about (135÷180) minutes.

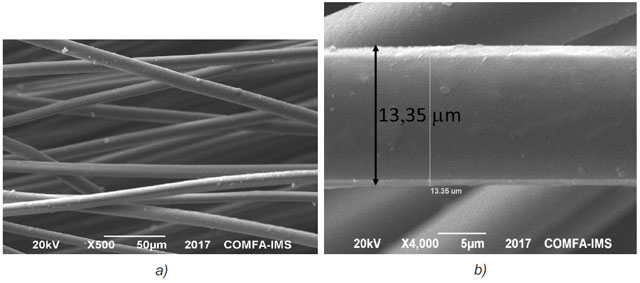

Using carbon mesophase materials synthesized as above mentioned, preliminary carbon fibers have been made (Figure 7). As seen in this figure, CFs exhibit a considerable uniform in size. Average size of the CFs is 500 nm in diameter and 700 mm and more in length. Figure 7 show only parts of three separate carbon fibers.

4. CONCLUSIONS

The obtained results demonstrated that the pitch of domestic coal with carbon content above 85 % and sulfur below 1.25 % completely meets the fabrication requirement of high modulus carbon fiber.

The temperature range for mesophase transformation in Thai-Nguyen coal pitch was determined as about (320 ÷ 350) °C.

The holding time for complete transformation to the mesophase in the coal pitch is (135 ÷ 180) minutes. The heating rate of 10 °C/h allows getting the best amount of pitch residue after heat treatment. Some technological parameters have been established for preparing mesophase pitch used in manufacturing of high modulus carbon fibers.

ACKNOWLEDGEMENT

This work was supported in part by the Research Institute for Application and Transfer of High Technology, VUSTA. The authors acknowledge the Institute of Energy and Mining Engineering (VINACOMIN) and the Institute of Applied Science and Research, the Hanoi Pedagogical University No 2 (HPU-2) for supporting in measurements of the composition and viscosity of coal pitch samples, respectively.

One of the authors (Tran Si Trong Khanh) expresses his sincere thanks to professors in the FEPN (VNU-UET) for their useful discussion.

REFERENCES

- Yuan and Z. Cui, Preparation, Characterization, and Applications of Carbonaceous Mesophase: A Review, Nematic Liquid Crystals, IntechOpen, 2019.

- Riggs M., Carbon fiber from solvent extracted pitches, Preprints Div. Petrol. Chem. Am. Chem. Soc., 29, 1984, 400.

- A.Newcomb, Processing, structure, and properties of carbon fibers, Composites Part A: Applied Science and Manufacturing, Vol. 91, 2016, 262-282.

- Brooks D. and Taylor G. H.; The formation of graphitizing carbon from the liquid phase, Carbon, 3, 1965, 185.

- Brooks D. and Taylor G. H.; The formation of some graphitizing. Carbon, Chemistry and Physics of Carbon, Vol. 4, Walker, P. L., Jr., Ed., Marcel Dekker, New. York, 1968, 243.

- Bacon , Carbon fibers from mesophase pitches, Phil. Trans. R. Soc. Land., A294, 1979, 437.

- Singer S., High modulus carbon fibers from mesophase pitches, in Ultra-High Modulus Polymers, Ciferri

- and Ward I. M., Eds., Applied Science Publishers,Essex, UK, 1979, 251.

- Riggs M., Shuford R. J., Lewis R. W.; Graphite fibers and composites, in Handbook of Composites, Lubin G., Ed., Van Nostrand Reinhold, New York, 1982, 196.

- Riggs P., Carbon fibers, in Encyclopedia of Polymer Science and Engineering, Vol. 2, John Wiley & Sons, New York, 1985, 640.

- Rand , Carbon fibers from mesophase pitches, in Handbook of Composites, Vol. 1, Strong Fibers, Watt

- and Perov V., Eds.; Elsevier, New York, 1985, 497.

- Matsumoto , Mesophase pitches and its carbon fibers, Pure Appl.Chem., 57, 1985, 1553.

- Singer S., Carbon fibers, in Concise Encyclopedia of Composite Materials, Kelly, A., Ed., Pergamon Press, Oxford, 1989, 47.

- Diefendorf J. and Riggs D. M.; Forming Optically Anisotropic Pitches, U.S. Patent 4, 208, 1980, 267.

- Yuan, Z. Jin, X. Zuo, Z. Xue, F. Yan, Z. Dong, Y. Cong, and X. Li, Effect of Carbonaceous Precursors on the Structure of Mesophase Pitches and Their Derived Cokes, Energy Fuels, 32, 2018, 8329−8339.

- Overview of petroleum coking coal, 2011, http://en.wikipedia.org/wiki/Pet blast_coke

- Coal pitch, SU standard, No 1038-75.

- Edie D. and Dunham M. G.; Melt spinning pitches based carbon fibers, Carbon, 27, 1989, 647.

- Ciesinska, Thermo-rheological properties of coal-tar pitch modified with phenol-formaldehyde resin, J Therm Anal Calorim Vol. 130, 2017, 187–195.

- Singer S., The mesophase and high modulus carbon fibers from pitches, Carbon, 16, 1978, 408.

- K.H. Briggs, Viscosity of coal tar pitch at elevated temperatures, Fuel, Vol. 59, 1980, 201-207.